Are you someone who is well acquainted with plastic? Are you trying to understand the differences between 3D printing and injection molding? If so, then you have put your sights in the right place.

In this article, we’ll go over the differences between 3D printing vs injection molding. We’ll talk about the similarities, too, of course, as well as some overall strategies and basic information on how each process works.

More interested? Then let’s get started!

Table of Contents

Process

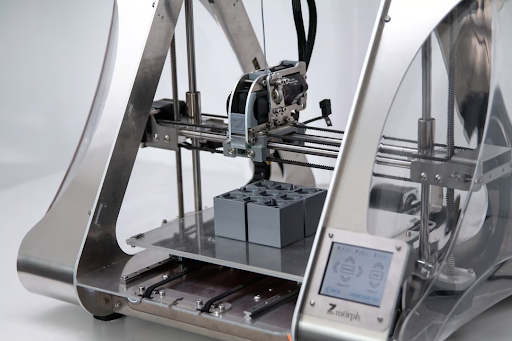

3D printing, also called “additive manufacturing,” builds things layer by layer from a digital model using different materials like plastics, metals, ceramics, or even biocompatible substances. For advanced applications in metal 3D printing, you can learn about dmls 3d printing here.

The injection molding technology is a type of subtractive manufacturing in which molten material (usually plastic) is forced under high pressure into a mold hole. Once the material has cooled and hardened, the mold is opened and the part comes out.

Design Complexity

3D printing is great for making prototypes, customized goods, and one-of-a-kind items with complicated shapes and designs. The process gives a lot of freedom in design and doesn’t need to use molds.

With injection molding, you can make a lot of parts with the same shape. Even though injection molding can make complicated parts, it usually costs more for molds with more details and may have design limits.

Cost

For mass production, 3D printing is more expensive per unit because it takes longer to make each one and the materials are more expensive. But it might be cheaper for testing and making a small number of items.

Injection molding has high starting costs because molds have to be made, but the cost per unit goes down a lot with larger production runs, making it a better choice for high-volume manufacturing.

Speed of Production

When it comes to big quantities, 3D printing is slower than injection molding. How long it takes to make something depends on how big and complicated it is.

Injection When making a lot of the same thing, molding is faster once the mold has been made and set up. Cycle time can be very short, which makes it possible to make a lot of things at once.

Material Selection

3D printing technology offers a wide range of materials, including plastics, metals, resins, and composites. However, material properties may be limited compared to those available in injection molding.

Injection Molding provides access to a broader selection of materials, including specialty grades, reinforced plastics, and elastomers.

Surface Finish and Quality

3D Printing has a layered appearance and may require additional post-processing to achieve a smooth surface finish. The mechanical properties may also vary depending on the types of 3D printers and material used.

Injection Molding produces parts with a smooth and consistent surface finish. It offers better mechanical properties and higher tolerances, making it suitable for more demanding applications.

Unraveling the Differences Between 3D Printing vs Injection Molding

Overall, both 3D printing and injection casting have their own benefits. 3D printing lets you make prototypes faster, with a bigger range of materials and a level of complexity that injection molding can’t match. On the other hand, injection molding uses tried-and-true methods and materials and is best for making a lot of parts at once.

To explore between 3D printing vs injection molding might be best for you, contact an expert today!

We hope this article was useful to you. If you enjoyed it, make sure to check out our blog for more informative content.