Are you considering a career in engineering? You’re in the right place. As one of the fastest-growing jobs in America, there’s never been a better time to chart your course in engineering. read more

As an engineer, you don’t just deal with complicated machinery and calculations. You have to have a way with people, as well. If a client comes to you with an issue and can’t resolve it, how will you earn their trust going forward?

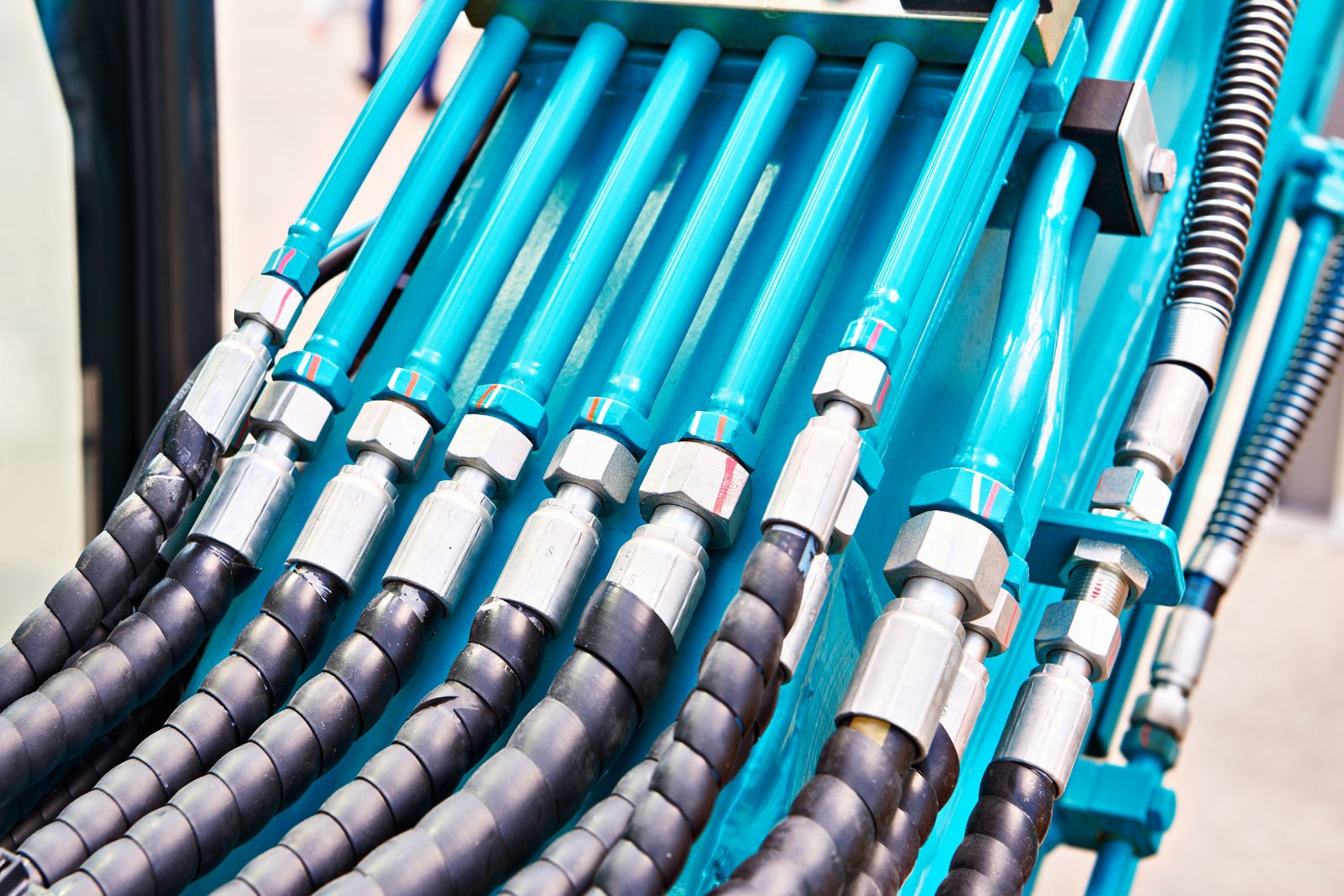

The ability to communicate, troubleshoot, and resolve conflicts is just as important as being able to design equipment. Below, we will elaborate on some of the most common hydraulic system components an engineer uses.

Table of Contents

1. Hydraulic Pump

The hydraulic pump is the primary power source of a hydraulic system. It plays a pivotal role in converting mechanical energy into hydraulic energy. This process involves pressurizing hydraulic fluid, typically hydraulic oil.

Hydraulic pumps come in various types, each suited to specific applications. For instance, gear pumps are simple and cost-effective, piston pumps offer high-pressure capabilities, and vane pumps provide reliable performance with low noise levels.

2. Hydraulic Cylinder

Hydraulic cylinders are needed to turn the hydraulic pressure made by the pump into a straight line of motion. These tools have a cylinder tube, a piston, and hydraulic seals.

When pressurized hydraulic fluid goes into the cylinder, it pushes on the piston, moving it in a straight line. Depending on the job, engineers choose between single-acting and double-acting cylinders. Single-acting cylinders only move in one direction when hydraulic pressure is applied, but double-acting cylinders can move in both directions.

3. Hydraulic Valves

Hydraulic valves are important parts that control the flow of hydraulic fluid and where it goes within the system. There are different kinds of hydraulic valves for different uses.

A directional control valves decide where fluid flow and are essential for controlling the movement of hydraulic devices like cylinders and motors. Pressure control valves adjust the pressure in a system so that it doesn’t get too high or stay the same.

Flow control valves are needed to control a hydraulic actuator’s speed precisely. In contrast, proportional and servo valves offer very exact flow and pressure control for applications that need high accuracy.

4. Hydraulic Reservoir (Tank)

The hydraulic reservoir, often called the hydraulic tank, is a storage vessel for hydraulic fluid. Its role extends beyond mere storage, as it also aids in maintaining fluid quality and system functionality. Hydraulic tanks facilitate the cooling of hydraulic fluid, preventing it from overheating during operation. Additionally, they allow air and foam to separate from the fluid, ensuring that only clean, air-free fluid enters the system.

5. Hydraulic Filter

Hydraulic filters are important parts of the system because they keep the hydraulic fluid in the system clean. Hydraulic parts can’t work well or last as long if they have dirt, trash, or particles.

Hydraulic filters catch and eliminate these contaminants, which protects the system and ensures it works well. To ensure optimal filtration, if you are seeking a reputable filter brand, consider Baldwin filters. These filters capture and remove these contaminants, preventing damage and ensuring the system’s reliability.

Turning Ideas Into Motion With Hydraulic System Components

Engineers rely on core hydraulic system components for a variety of applications. The power to transform the modern industry comes with the mastery of understanding these hydraulic components. Use only the best and most highly rated hydraulic system parts today!

Did you learn something new from this article? If so, be sure to check out our blog for more educational content.