In every industry, complex machinery and equipment are used to shape our modern world, from manufacturing and transportation to energy production and beyond. While these colossal systems might take the spotlight, it’s often the tiniest components that play a pivotal role in ensuring seamless operations and sustained productivity. Seal and bearing solutions are being revamped with next-generation advancements to empower industries in new ways. Eclipse Engineering is one of the great suppliers and manufacturers of quality seal and bearing products having the intent of finding solutions for every application in a particular and improved manner.

A Foundation of Precision and Resilience

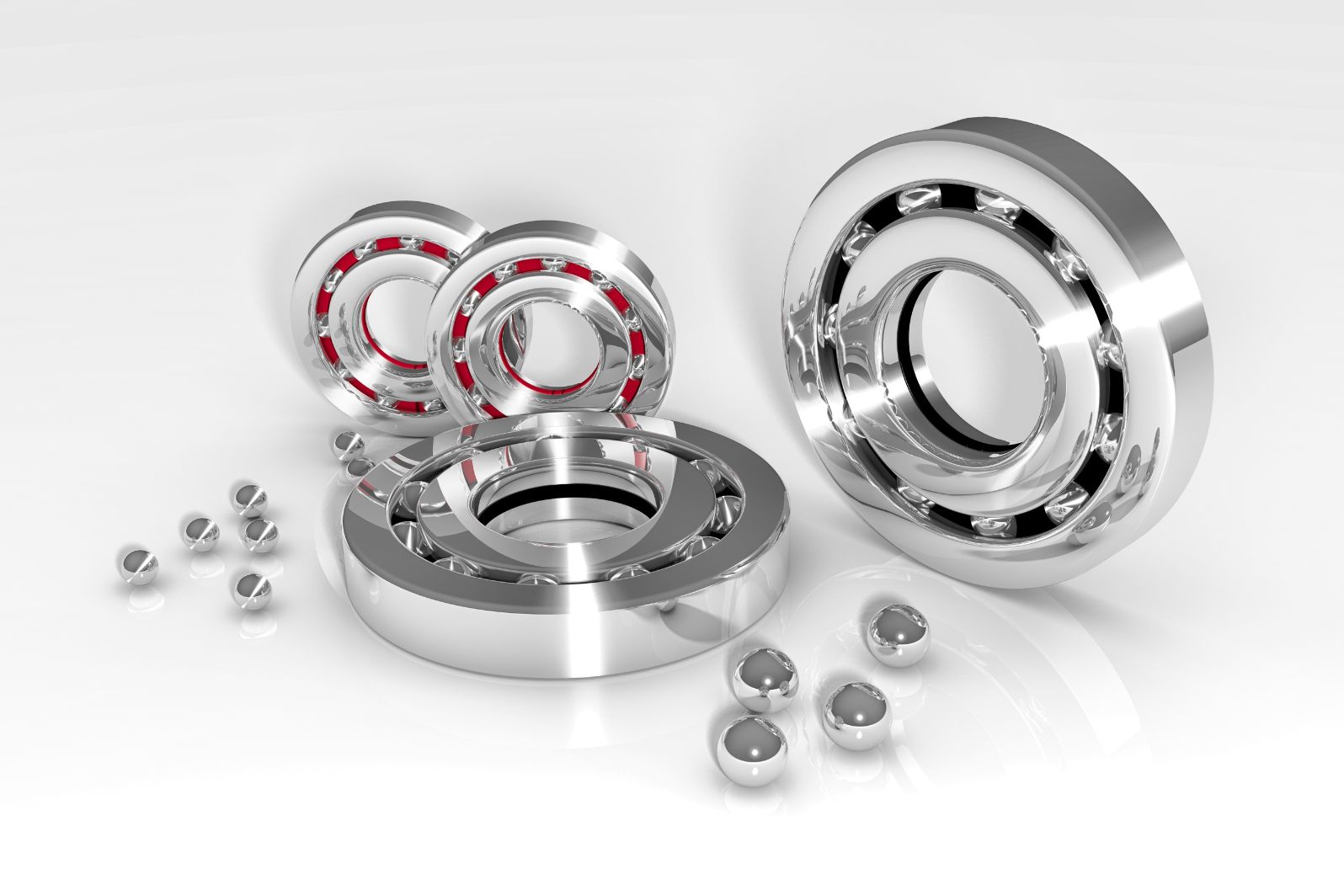

Seals and bearings, while seemingly minuscule, are the very linchpins that maintain the delicate balance between friction and motion, efficiency and inefficiency. Bearings, ranging from conventional ball and roller bearings to cutting-edge magnetic and ceramic variants, provide the necessary support for rotational or linear movement, minimizing friction and enabling smooth operation. Meanwhile, seals form impenetrable barriers, guarding against contamination infiltration and lubrication leakage, thereby enhancing the lifespan and functionality of critical components.

As industries grow more demanding, requiring higher speeds, greater loads, and resistance to harsh environmental conditions, the role of these components becomes even more crucial. The latest breed of seal and bearing solutions are engineered to be more than just cogs in a machine; they are designed to be dynamic enablers of progress.

Challenges as Catalysts for Innovation

Industrial settings are rife with challenges that push the boundaries of machinery and components. Seals and bearings, constantly subjected to intense forces, extreme temperatures, and corrosive agents, inevitably face wear and tear over time. However, it’s these very challenges that spur innovation in materials, designs, and manufacturing techniques.

Advanced ceramics are emerging as formidable contenders in bearing technology, boasting remarkable heat resistance, superior strength, and a knack for reducing friction. Elastomeric seals, fortified with specialized coatings, defy corrosive substances and extend their service life in harsh environments. Engineers and scientists, driven by the pursuit of efficiency and sustainability, are forging new paths in material science to create components that don’t just cope with challenges but conquer them.

The Nexus of Performance and Predictability

Seal and bearing solutions, reimagined for the modern era, aren’t merely static components – they’re intricate pieces of a larger puzzle, powered by innovation and data-driven insights. The integration of sensor technology and the Internet of Things (IoT) is ushering in a new era of predictive maintenance. Real-time monitoring, coupled with sophisticated algorithms, allows industries to predict when seals and bearings might require attention, preventing catastrophic failures and minimizing downtime.

This marriage of precision engineering and intelligent monitoring is revolutionizing maintenance practices. No longer do industries have to wait for visible signs of wear or rely on fixed maintenance schedules; now, they can intervene at precisely the right moment, maximizing operational efficiency and stretching the lifespan of machinery.

The Road Ahead: Pioneering Possibilities

The future of industries is intertwined with the evolution of seal and bearing solutions. As technology continues to leap forward, we can expect further integration of smart technologies, perhaps even self-monitoring and self-repairing components. Imagine a scenario where a bearing senses its own performance decline and deploys a micro-adjustment to restore optimal function. The potential for increased efficiency, reduced waste, and amplified productivity is staggering.

In conclusion, next-generation seal and bearing solutions are catalysts of transformation in industries worldwide. They embody the spirit of innovation, resilience, and adaptability that characterize the modern era. As industries continue to reach for higher peaks of achievement, these components will remain at the forefront, supporting progress in ways that not only defy expectations but reshape the very fabric of industrial empowerment.