Some things just wouldn’t work without ball bearings. Cars and planes could get nowhere without them, in fact. Their existence makes modern life possible, at least in more ways than one.

In this article, we’re taking a closer look at these amazing bearings. We’re providing an overview of their history as well as explaining the types of ball bearings one might find. They don’t get a lot of thought, but once you start thinking about them, it’s hard to stop.

You might even be wondering, “How many types of ball bearings are there?” We can answer that question for you. Keep reading to find out more.

Table of Contents

Angular Contact Ball Bearings

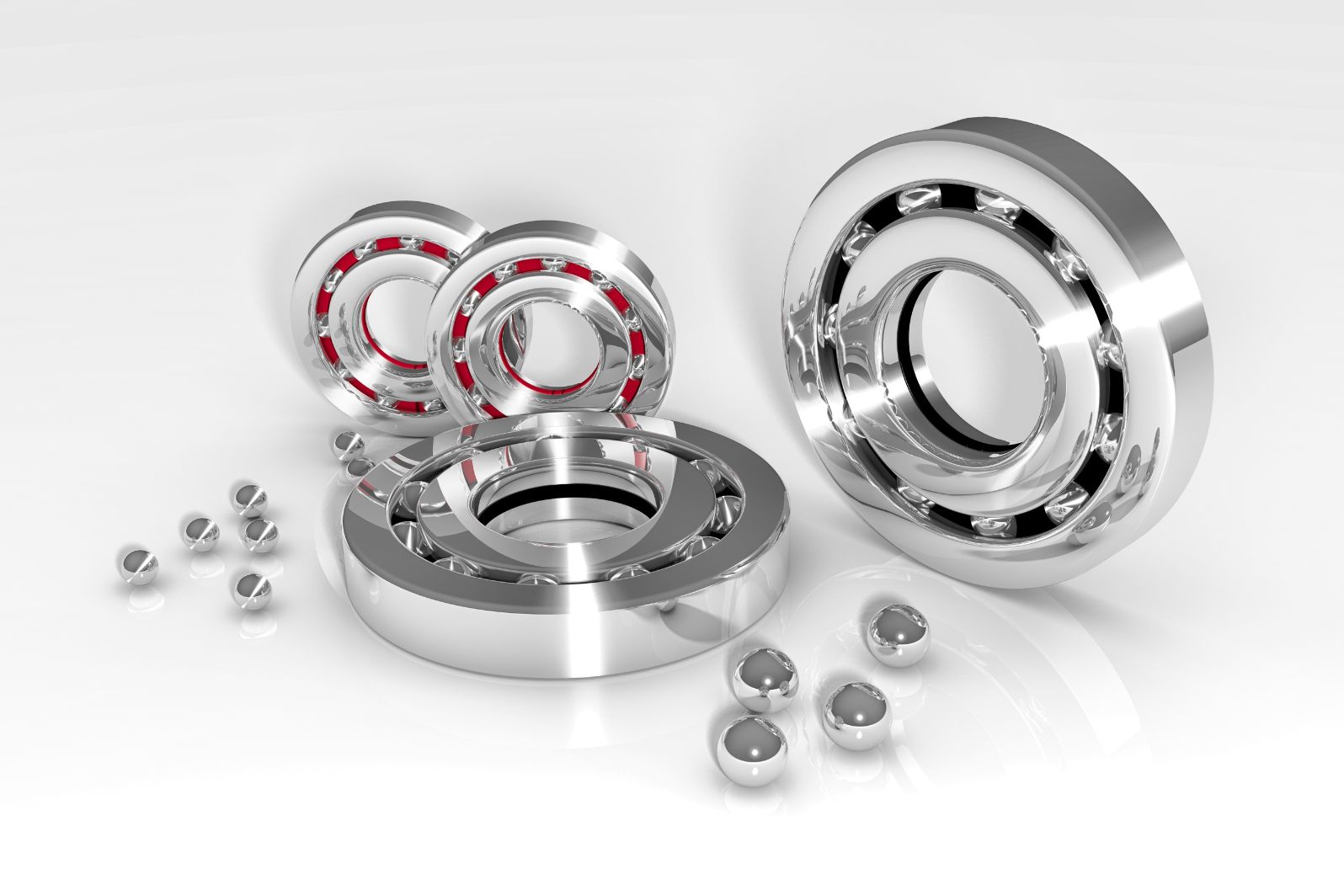

Angular contact ball bearings are ball bearing types of rolling-element bearing. They can carry radial and axial loads simultaneously in both directions. They consist of an inner and outer race and a set of ball-shaped elements rolling between them.

The main feature of angular contact ball bearings is that the line of contact between the ball and inner and outer race is at an angle, which allows them to bear both radial and axial loading. The balls are equally distributed arrangements in order to achieve higher speed and stability. Angular contact ball bearings are used in a variety of applications, including electric motors, pumps, fans, and aerospace equipment.

Uber Bearings

Uber bearings are a type of bearing that provides a cost-effective and reliable solution for a variety of needs. These self-lubricating bearings can be used in a variety of applications, from medical to industrial. They can also improve the performance of a machine or device, reduce vibration, and provide noise reduction.

The bearing has an outer ring, inner ring, and rolling elements such as balls or rollers. It also includes a lubrication system, designed to reduce frictional energy and prolong the lifespan of the device. With its easy installation and maintenance, uber bearings are increasingly gaining popularity across the world.

Grooved Ball Bearings

They have a series of grooves, or indentations, around the inner and outer rings. These grooves act as a raceway for the balls, allowing them to rotate freely in any direction. The ball bearings also have a low amount of friction between the rolling elements which allows for smooth and efficient operation.

They are often used in applications that involve high speeds and require accuracy. They provide excellent support to rotating components and have a very low noise signature. They are an efficient and cost-effective solution for most ball bearing applications.

Learn the Most Popular Types of Ball Bearings Today

When it comes to ball bearings, it’s important to understand that there are many types of ball bearings to choose from. From angular contact ball bearings to grooved ball bearings, the type of ball bearing chosen should always be based on the application and requirements of the project. For more information, contact an expert-bearing supplier today!

If you find this helpful and want to read more great content, check out our latest blog posts now!