Choosing the right equipment for cutting sheet metal is crucial for achieving clean, precise cuts and ensuring efficiency. With various tools available, from manual shears to advanced laser cutters, the decision depends on the type of metal, thickness, and your specific project needs.

Whether you’re a DIY enthusiast or a professional, understanding the capabilities and limitations of each tool is essential to get the best results. This guide will help you navigate the options and choose the right equipment for your sheet metal cutting tasks. Keep on reading!

Table of Contents

Understand Your Material

Before you start cutting, it’s important to know details about the sheet metal you’re working with. Different metals have varying levels of hardness and thickness. For example, aluminum is softer than stainless steel, and both require different tools for cutting.

Knowing the thickness of your sheet metal is also essential. Thin sheets can often be cut with hand tools, while thicker metals may require power tools. Understanding these properties will help you make informed decisions about the tools you’ll need.

Consider the Type of Cut

The type of cut you need will also influence your choice of equipment. Straight cuts are the simplest and can be achieved with basic tools like tin snips. Tin snips are small and handy, making them ideal for quick, straight cuts on thin sheets of metal.

For more complex cuts, such as curves or intricate shapes, you’ll need more specialized tools. Tools like jigsaws or plasma cutters are designed to handle these types of cuts efficiently. Selecting the right tool for the type of cut can save you time and improve the quality of your work.

Manual vs. Power Tools

When it comes to cutting sheet metal, you have the option of using manual or power tools. Manual tools, such as tin snips and hacksaws, are great for smaller projects. They are easy to use and don’t require any power source, making them convenient for quick tasks.

Power tools, on the other hand, are better suited for larger projects. Tools like angle grinders and electric shears can cut through metal quickly and with less effort. While they may require a bit more investment upfront, they can save you a lot of time in the long run.

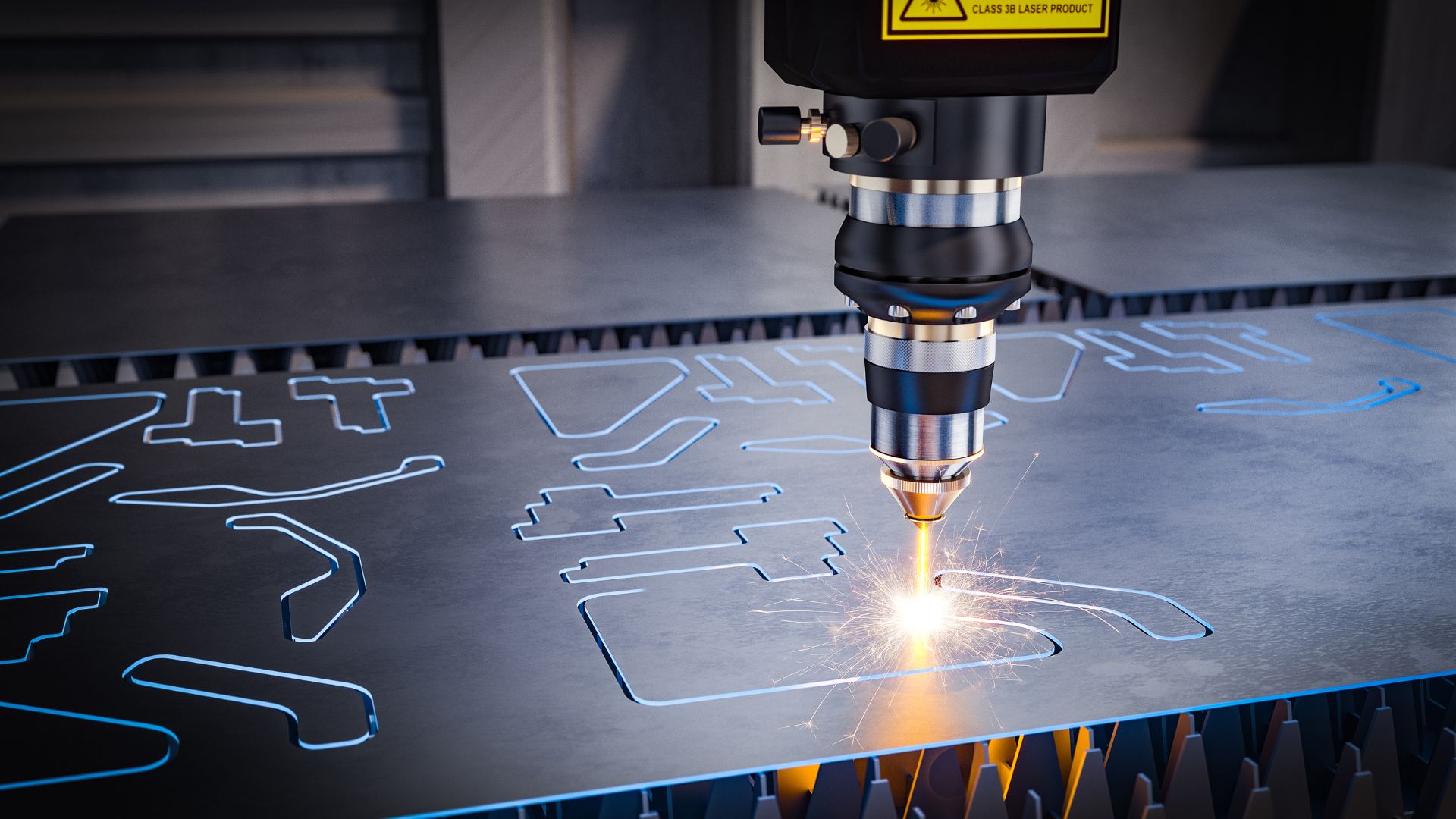

If you want to explore more efficient cutting methods, consider laser cutting. A lot of businesses are now investing in this type of technology for the benefits it offers.

Safety First

Safety should always be a top priority when working with sheet metal. Sharp edges and flying metal fragments can cause serious injuries. Always wear protective gear, including gloves and safety glasses, to protect yourself.

Additionally, make sure you are familiar with the safety features of your equipment. Many power tools come with guards and other safety mechanisms. Understanding how to use these features will help you work more safely and efficiently.

Budget Considerations

Your budget will also play a significant role in your choice of equipment. Manual tools are generally more affordable than power tools. However, they may require more physical effort and time to complete a project.

Power tools are usually more expensive but offer greater efficiency and precision. Investing in high-quality tools can pay off in the long run, especially if you frequently work with sheet metal. Weighing the costs against the benefits will help you make an informed decision.

Popular Metal Cutting Tools

Cutting sheet metal is a common task in many DIY and professional projects. Knowing the right tools can make the job easier and produce cleaner results. Here are some popular tools for cutting sheet metal:

Tin Snips

Tin snips are basic hand tools resembling scissors, perfect for making small, straight cuts or slight curves in sheet metal. They come in three main types, each suited to specific tasks. Straight-cut snips are ideal for making straight lines, while left-cut snips are designed for cutting curves to the left, and right-cut snips are best for cutting curves to the right. These variations allow for greater precision and versatility when working with different shapes and designs.

Hacksaw

A hacksaw is a versatile tool with a fine-toothed blade. It can cut through metal sheets but requires more effort compared to other tools. A hacksaw is best for straight cuts and small projects.

Electric Shears

Electric shears are power tools that can cut through sheet metal quickly. They are great for large projects and straight cuts. Some electric shears also handle curves, making them versatile for various tasks.

Angle Grinder

An angle grinder is a powerful tool that can cut through thicker sheets of metal. It uses a rotating disc to slice through the material. Angle grinders are fast and efficient but require caution due to their power.

Nibbler

A nibbler is a tool that removes small bits of metal as it cuts. It can make precise cuts and handle complex shapes. There are manual and electric nibblers available, making them suitable for various jobs.

Plasma Cutter

A plasma cutter is a high-tech tool that uses a jet of hot plasma to cut through metal. It is very precise and can handle thick sheets. Plasma cutters are ideal for detailed work and heavy-duty projects.

Maintenance and Care

Proper maintenance of your tools is essential for ensuring their longevity and performance. Regularly clean your tools to remove any metal fragments and debris. Lubricate moving parts to keep them functioning smoothly.

Storing your tools in a dry, safe place will also prolong their lifespan. Moisture can cause rust and other damage, so make sure your storage area is well-ventilated and dry. Taking good care of your tools will ensure they remain effective for years to come.

Explore the Many Ways of Cutting Sheet Metal

Choosing the right equipment for cutting sheet metal involves understanding your material, considering the type of cut, and weighing the pros and cons of manual vs. power tools. Safety should always be a priority, and your budget will also influence your decision. By considering these factors, you can select the best tools for your needs and achieve excellent results in your metal-cutting projects.

For more topics aside from precision metal cutting, visit our blog!