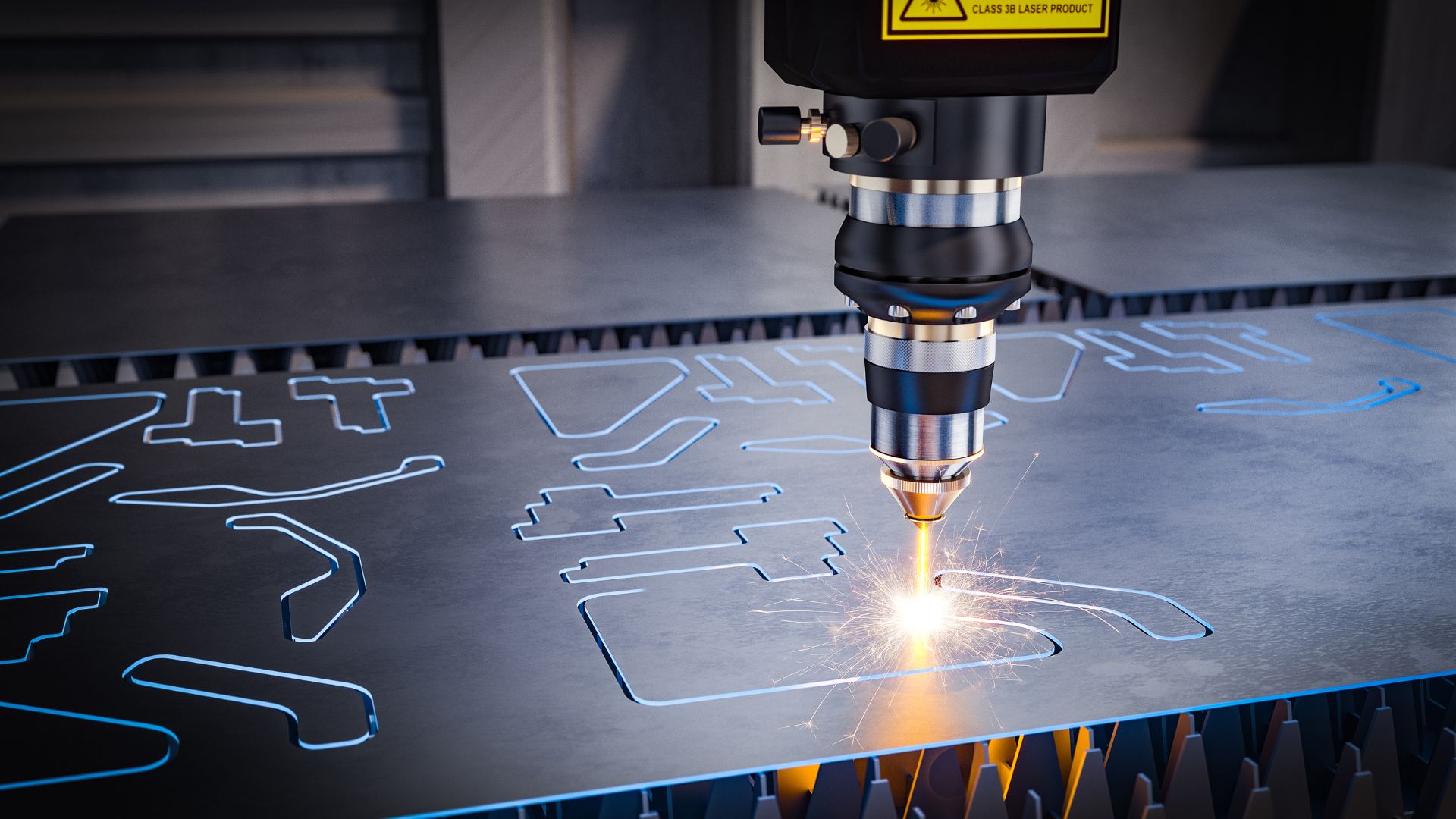

How do you pick the right laser metal cutting machine for your business?

With so many choices out there, it can feel overwhelming. Start by knowing what you need. Are you looking for high accuracy, fast speed, or flexibility?

The right laser metal cutting machine can take your work to the next level. Look at things like power, ease of use, and upkeep. Each detail helps you find the best machine for your needs.

Read our guide to learn how to choose a laser metal cutting machine that fits your business and boosts productivity.

Table of Contents

Determine Your Material Needs

Choosing the right laser metal cutting machine begins with knowing what materials you will be cutting. Different metals and thicknesses need a specific laser cutter for metal settings to work best.

Think about the types of metals you use, like steel, aluminum, or copper, and how thick they are. Also, consider how often you will cut these materials. It’s important to pick a machine that fits these needs to make sure your work is accurate and efficient.

Matching the machine to your material needs helps avoid mistakes and keeps your work smooth. For special tasks like UV laser cutting, check that the machine can handle those features.

Consider Power and Speed

Power and speed are important when picking a laser metal cutting machine. Machines with higher power can cut thicker metals quickly and accurately. But, more power usually costs more money.

Find a balance between your budget and your production needs. Speed matters too; faster machines can boost productivity and save time. Look at how fast the machine cuts and how well it handles different materials.

If you use various metals, adjustable settings are helpful to get the best results from your metal cutting laser. By thinking about both power and speed, you can choose a machine that fits your needs and works efficiently.

Evaluate Maintenance Requirements

Maintenance is important when picking a laser metal cutting machine. Regular upkeep keeps the machine working well and lasting longer. Check how often it needs servicing and which parts might need replacing often.

A metal cutting laser that doesn’t need much maintenance can save you time and money. Choose machines that are easy to clean and have parts you can reach easily. Training your team on how to take care of the machine also helps reduce downtime.

Knowing the maintenance needs will help keep the machine running smoothly. By thinking about these factors, you can pick a machine that fits your business and keeps production moving.

Check Software Compatibility

Software compatibility is important when picking a laser metal cutting machine. Make sure the machine’s software works with your current systems. This will make things run smoothly and save time on training.

Choose software that is easy to use and fits with programs you already have. Good compatibility stops work problems and helps you get more done.

By focusing on software compatibility, you can ensure your metal cutting laser works well and fits into your business easily.

Mastering Laser Metal Cutting for Your Business

Choosing the right laser metal cutting machine can help your business a lot. By looking at maintenance needs and software compatibility, you can make sure everything runs smoothly and efficiently.

A good machine saves time, cuts costs, and keeps your work moving. Taking time to check these things helps you get the best results from your metal cutting laser. With the right choice, your business will be more successful and competitive.

Did you find this article helpful? You can check out our website for more awesome content like this.