Cotton has always been a labor-intensive crop. This is one of the reasons that slavery and then sharecroppers existed. The development of a mechanical picker significantly reduced the amount of manual labor required.

John Deere is hoping to revolutionize cotton harvesting with a new vehicle. It will use an autonomous electric vehicle with robotic arms mounted to it to do the work.

Table of Contents

1. Increased Sustainability

Cotton harvesting is a very labor-intensive process. As a result, it requires the use of various agrochemicals to protect the plant from insects and diseases. Cotton production also uses a significant amount of water. This water is diverted from surface and ground sources to irrigate the cotton fields, leading to freshwater loss through evaporation and environmental pollution. This is a serious problem as it negatively affects major ecosystems such as the Aral Sea in Central Asia and the Indus Delta and Murray Darling River in Australia.

Moreover, the monocultural nature of cotton farms leads to erosion of soil quality. As a result, the natural ability of the soil to filter water and sequester carbon is compromised. Additionally, the use of chemicals to protect the cotton plants from pests and diseases damages the biodiversity in the surrounding environment.

Farmers in third-world countries feel the effects of this most acutely, as they often struggle to cover their living expenses. To increase their income, they have to rely on expensive agrochemicals, which are harmful to human health and degrade the soil. The erosion caused by cotton farming also contributes to the loss of habitat for wild animals.

To make up for these negative ecological impacts, the Sustainable Trade Foundation IDH is working to help smallholders adopt regenerative growing practices. The organization’s Climate-Smart Cotton Landscapes program helps smallholders become resilient to climate change and improve their income by focusing on the whole landscape rather than just individual farms.

In addition, IDH is also helping smallholders to understand the environmental footprint of their cotton using an analysis tool called Fieldprint. Using this, cotton producers can calculate their own environmental impact and report it to their buyers. This gives buyers another way to support regenerative cotton, in addition to sourcing from known sustainable brands. This level of transparency will be necessary if the future of cotton is to be sustainable and climate-friendly. Achieving this will require that the entire supply chain, from farmer to consumer, is able to identify and communicate the environmental impact of their cotton products.

2. Increased Efficiency

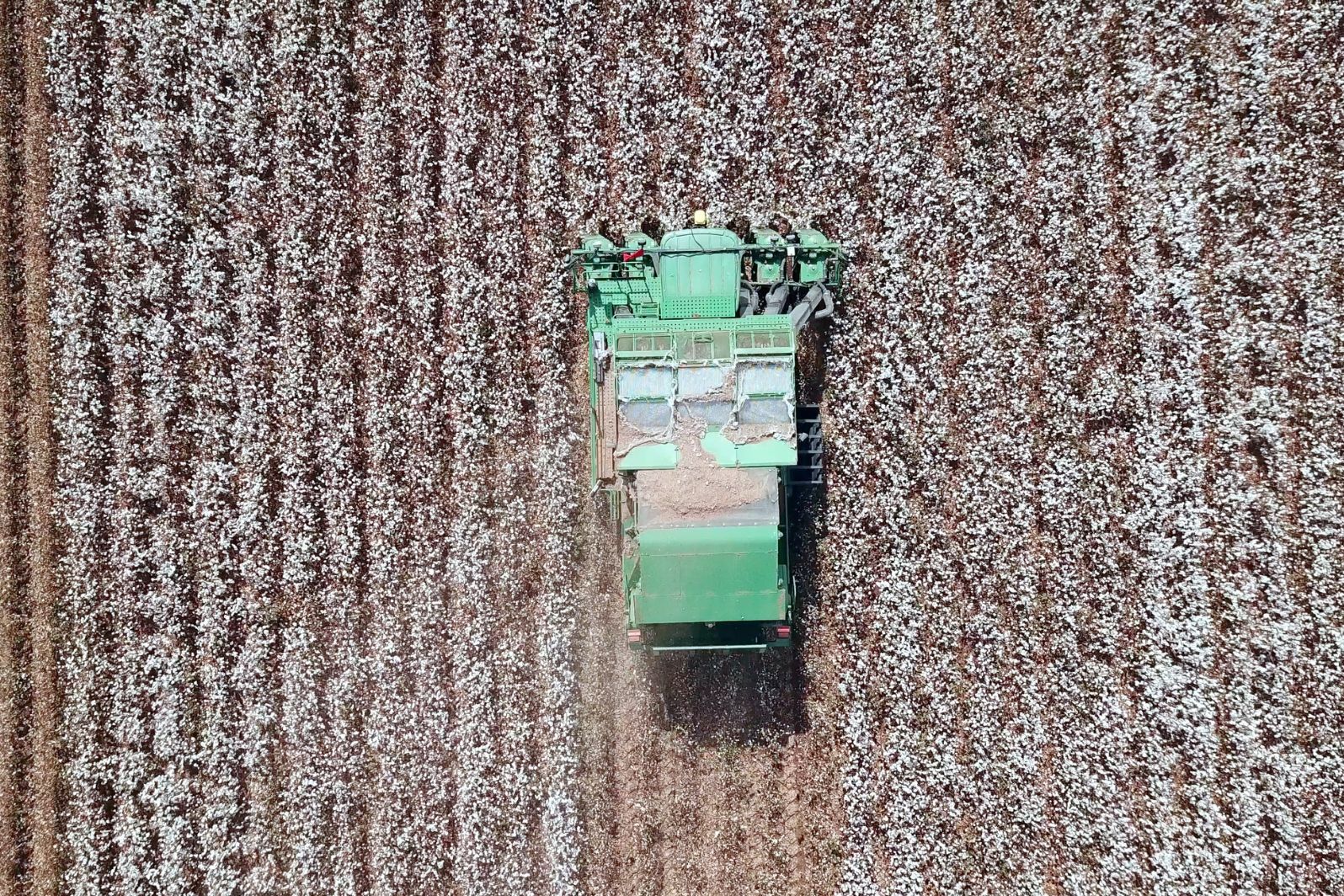

As the demand for cotton textiles increases, farmers are increasingly turning to mechanization to ease production and harvesting. As a result, the cotton harvester market is expected to grow by 6% over the forecast period, reaching nearly 119 million bales in 2021/2022.

Cotton harvesters are a vital piece of equipment for farmers, and the quality of the machine determines its efficiency. Choosing an efficient cotton picker requires an evaluation of many factors, including ergonomics, fuel efficiency, durability, and environmental impact. Farmers should look for a manufacturer that prioritizes technological advancements, offers new upgrades to improve picker performance, works closely with rebuilders and farmers, and provides exceptional customer support.

The well-being and comfort of the operator also influence harvester efficiency. Choosing a machine with ergonomic features like air-conditioned cabins, adjustable seating, and user-friendly controls can boost operator morale, reduce fatigue, and increase productivity. Additionally, selecting a cotton harvester with low emissions engines and advanced filtration systems minimizes the machine’s carbon footprint and helps farmers achieve their sustainability goals.

Another factor that influences harvester efficiency is its ability to prevent damage to the crop. Choosing a machine with sensors that monitor the field and prevent accidental damage can significantly increase a farmer’s productivity. The sensors can identify and alert the operator of any potential threats, such as debris blocking the conveyor belt or excessive speeds that could damage the harvester.

More automation is a key trend in the cotton harvester industry, and several research presentations at the 2022 Beltwide Cotton Conferences highlighted this innovation. For example, Hussein Gharakani, a graduate research assistant at Mississippi State University, shared results from his studies on robotic cotton harvesters. These machines mimic human picking, allowing bolls to be harvested in multiple cycles and eliminating the need for defoliation. Additionally, they can limit soil compaction by limiting passes of heavy equipment across the field.

These advances in technology are helping to make cotton harvesting faster and more accurate. They are also boosting the profitability of small farmers who struggle to hire laborers to manually pick their fields. According to a study, these farmers are mostly located in rural areas with poor-quality land and rely on leased cotton harvesters and other mechanized equipment for their livelihoods.

3. Increased Flexibility

Cotton harvesters are used to collect, remove, and process lint, or cotton seeds, from the bolls of the plant. These machines come in a variety of styles, depending on the kind of harvesting they are designed to do. Some are mechanical, using spindles or fingers to open the bolls and remove the lint without damaging the plant. Others are pneumatic, using air blasts or suction to remove the lint from the plant. Still, others use electricity, exploiting the static buildup of electric charges in the cotton to draw it out of the bolls and into a collection basket or baler.

In addition to these mechanical and pneumatic cotton harvesters, researchers are working on a range of other innovative ways to make the cotton industry more sustainable and efficient. For example, breeders have developed hybrid varieties that ripen uniformly, so the harvester does not need to pass over the same bolls multiple times. Scientists have also figured out how to defoliate the plants before they are picked, which helps prevent the bolls from being damaged by the harvester.

However, the biggest challenges to mechanizing the cotton harvest remain. The first is that local workers, such as migrant and indigenous people from Mexico and Latin America, are opposed to mechanizing the harvest. They point out that if cotton harvesting mechanization is successful, it will negatively affect the wages they receive for their other daily agricultural work. This would be a disaster in the cash-strapped regions where many of these workers live.

To overcome this resistance, some companies are developing cotton harvesters that are less invasive to the worker and more human-friendly. For example, Indian start-up Green Robot Machinery has developed a robotic cotton picker that uses autonomous robotic arms mounted on a semi-autonomous electric farm vehicle. The robot is capable of picking 50 kgs of cotton per day, and four of these arms put together can pick about 200 kilograms per day – the average yield for a cotton field in India. This system can be added to existing tractor-mounted cotton harvesters, making them more human-friendly for migrant and indigenous workers.

4. Increased Productivity

Cotton harvesting/picking is a time-consuming process that involves labor and mechanical tools. Using a cotton picker machine helps reduce human effort and saves time. However, the adoption of this technology has not been widespread due to a lack of awareness and high prices. However, with the advent of organic Pima and demand rise, cotton mechanization has gained momentum. This will accelerate the cotton harvester market growth over the forecast period.

The use of advanced cotton harvesters allows farmers to increase their yield and efficiency. These machines also help in minimizing the damage to the crop by using sensors and monitors. Moreover, they offer greater flexibility and accuracy compared to manual harvesting processes, thus contributing to their popularity among farmers. Increasing production of cotton around the world, growing cotton textile consumption, and technological advancements are some of the major factors driving the demand for cotton pickers worldwide.

Manufacturers of cotton harvesters are focusing on designing simple and user-friendly machines to meet the growing needs of consumers. For instance, they are using sensors, GPS, LCD monitoring systems, and automated harvest mapping to improve the performance of their machines. This helps them to create more efficient products and gain a competitive edge in the market.

In addition to this, the cotton harvesters’ market is gaining momentum from the increased demand for organic fibers globally. Furthermore, the cotton mills in the United States are implementing new technologies to enhance the productivity and quality of their product. Moreover, the rising demand for cotton in countries such as China and India has driven up the global market for cotton harvesters.

Before investing in a cotton picker, farmers should evaluate their individual harvesting requirements and budget. They should consider factors such as farm size, variety of crops grown, and labor availability. In addition, they must select a machine that is capable of picking the crops in a short time span. Moreover, they should ensure that the cotton picker has a good track record of durability and reliability. This will help them to minimize the operational and maintenance costs.